Vertical type sealing and shrinkage equipment POF film sealer shrinking tunnel for cosmetic boxes disposable hotel clothes electronics

Basic parameters of vertical type sealing and shrinkage machine:

Technical Parameters of the Machine

Model YX-750LB

Power Supply 3& 415V 50Hz

power 4kw

Air supply pressure 6~8kg/mm2

Packaging speed

It varies according to the size of different

packages (0-40 pieces/minute)

Sealing and cutting size

Electric height adjustment

Maximum sealing size; L unlimited, W +H

≤700mm

H≤230mm

weight 400kg

The auto side sealing shrink packaging machine is a vertical up and down sealing and cutting shrink packaging machine designed for the refined production of cosmetic films. Mainly for high and thin products, it can automatically complete the steps of feeding, film wrapping, sealing and cutting, shrinking, etc., to ensure that the sealing line is in the middle position, auto film blowing, and the sealing line is thin, suitable for POF film and adhesive film. The heat shrinkable packaging effect is beautiful, smooth and wrinkle-free, no need for personnel to operate, the packaging speed is 5-40 pcs/min, and the work efficiency is high. This sealing and shrinking packaging machine is also suitable for printing, color box, medicine, daily chemical, auto parts, food and other industries.

PENGLAI shrink packaging machines deliver an excellent combination of price, versatility and customer support. With a comprehensive line of durable shrink wrapping machines, we offer the packaging solution you require and deliver the value you seek.

Customized to your needs • Individual and flexible.

From l-bar sealers to high-speed automatic shrink packaging systems, PENGLAI offers a wide range of shrink packaging machines. This enables us to fit the right mix of features and options to suit any customer’s production needs

.

Here are some things you can expect:

·A review of your current packaging processes and suggestions for improvements.

·A plan for how to right-size machine platforms for speed and complexity to match your current—and future—production demands.

·Examples of how packaging automation was successfully implemented in businesses similar to yours.

·Suggestions for new packaging equipment that will dramatically increase productivity and efficiencies.A

1. Overview

Thank you very much for purchasing our products. What you are using is a safe,

practical and efficient small edge sealing packaging machine.

2. Notes to Manual

A. Please read this manual carefully before using the machine;

B. Please use the machine after mastering the knowledge and precautions of the

machine;

C. Please keep this manual properly for reference at any time;

D. Be sure to give this manual to the end user;

E. Due to continuous improvement and improvement of machine performance,

the company reserves the right to modify the machine and manual;

F. If you have any good suggestions on this manual or the machine, please contact

our company;

3. Safety precautions

A. The circuit breaker and power cord with the same capacity as the machine

must be used. The use of circuit breakers with smaller capacity or power lines

with smaller wire diameters will cause damage to lines or components;

B. When packaging the liquid, it shall be ensured that the liquid will not drip. If

this machine is used to pack liquid objects with poor sealing, it may cause

damage to the machine or electric shock to people;

C. Do not use the machine in a highly humid environment, nor let the machine be

exposed to a large amount of water vapor;

D. Do not use or place the machine in dusty places;

E. The parts with high temperature warning signs may be exposed to high

temperature during operation, so please do not touch them with your hands;

F. When replacing parts, cut off the power supply first and replace them according

to the correct steps.

4. Machine performance

A. This machine is suitable for the appearance packaging of food, electronics,

toys, books, electrical appliances, bamboo and wood tools, hardware tools,

cosmetics, drugs, etc. After packaging, it has beautiful appearance,

moisture-proof and scratch proof functions, improving the product image and low

packaging cost;

B. The sealing height can be adjusted, and the length of packaged products is

unlimited;

C. High quality brand control components are used to ensure stable and reliable

operation and low failure rate;

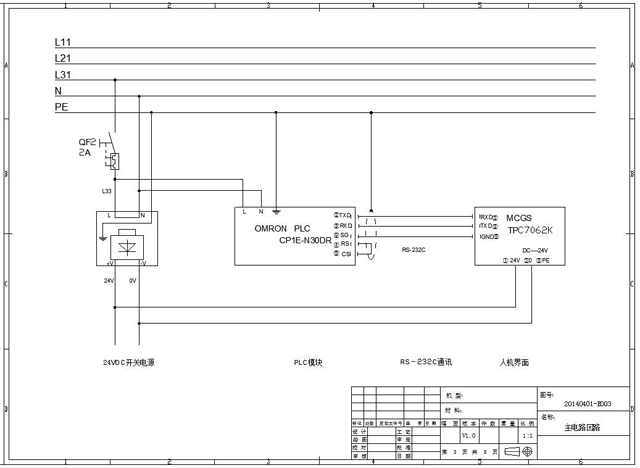

D. The operating system is equipped with a humanized color touch screen, which

is easy to understand with pictures and texts;

E. The sealing knife is made of special materials, which has high strength and is

not easy to deform. It is coated with DuPont Teflon, which is resistant to adhesion

and high temperature. The sealing is stable and firm.

F. The conveying motor adopts the brake function, which makes the movement

more accurate;

G. This machine is suitable for all kinds of shrinkable films such as POF, PE, etc.

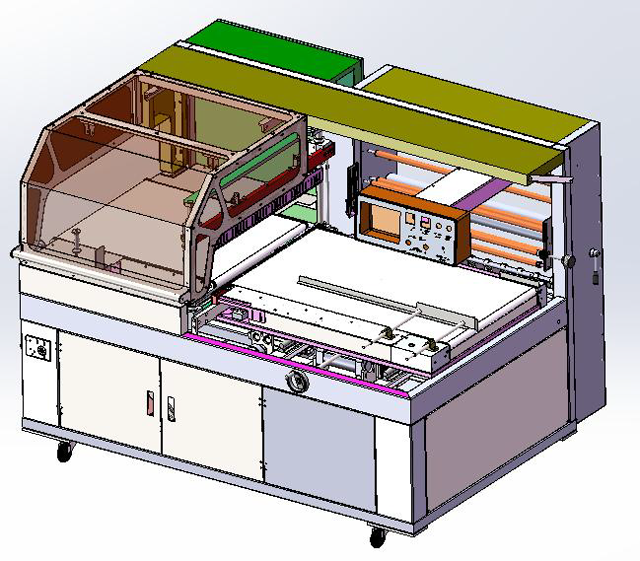

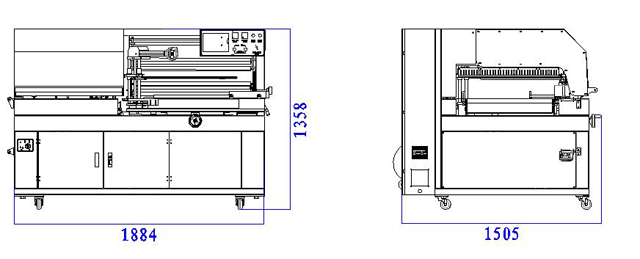

Machine appearance dimension

1、External dimensions of the machine

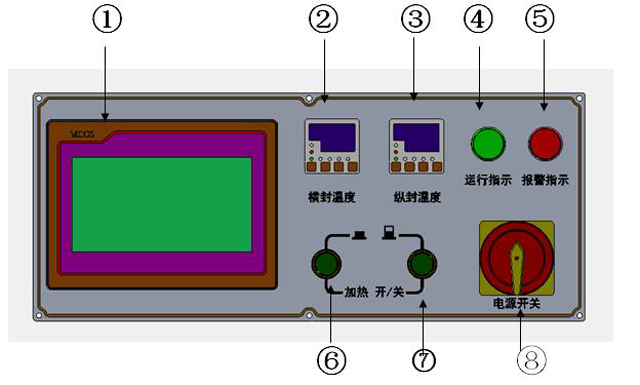

Name of Machine Panel and Components

1. Touch screen: operation interface and setting machine parameters;

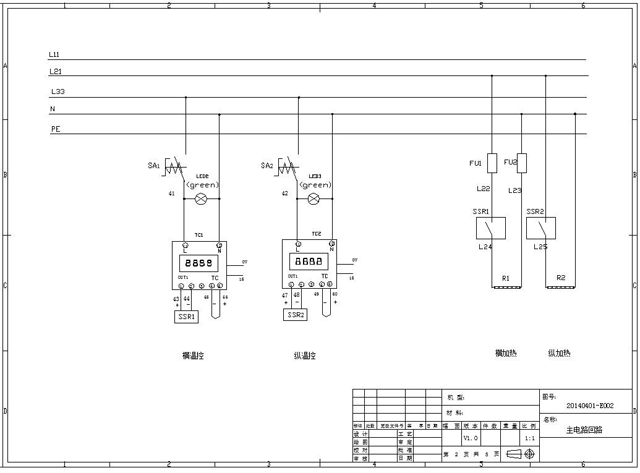

2. Horizontal sealing temperature controller: set heating temperature;

3. Longitudinal sealing temperature controller: set heating temperature;

4. Running indicator: the machine will run automatically when the light is

on, otherwise it will stop automatically;

5. Alarm indicator: alarm;

6. Horizontal seal heating switch: switch;

7. Vertical seal heating switch: switch;

8. Power switch: turn off or connect the main power supply of the machine;

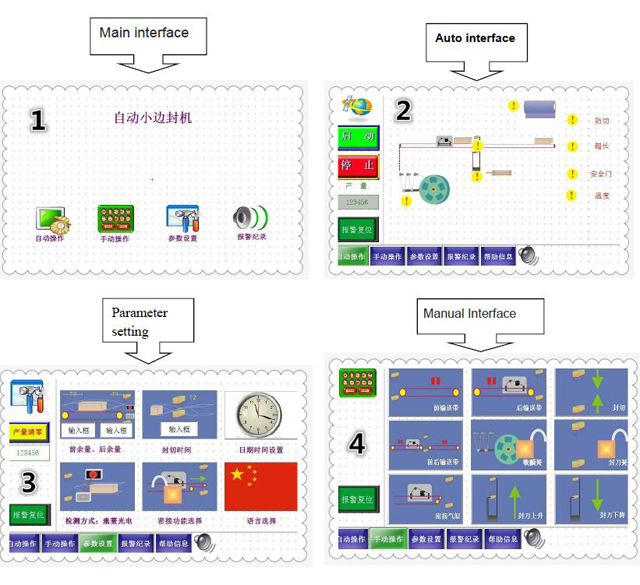

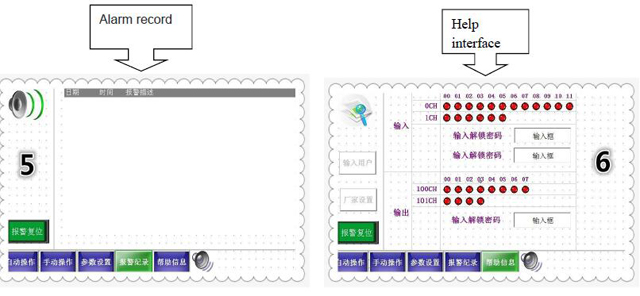

Main interface Auto interface

Parameter

setting

Interface

Manual Interface

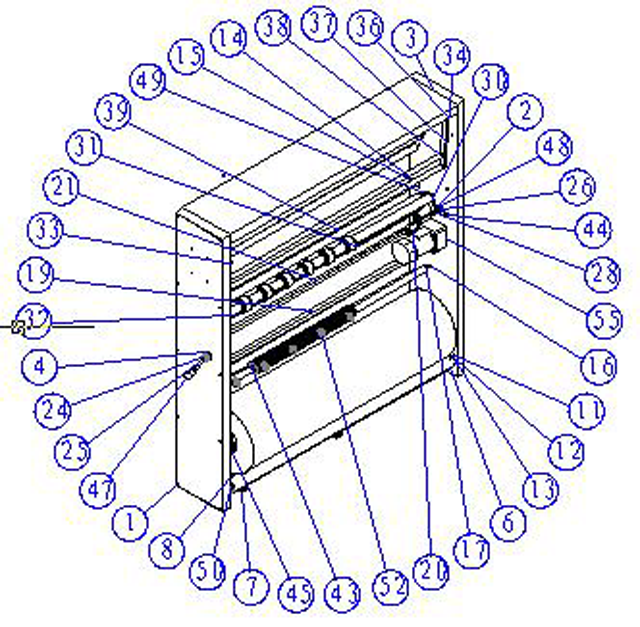

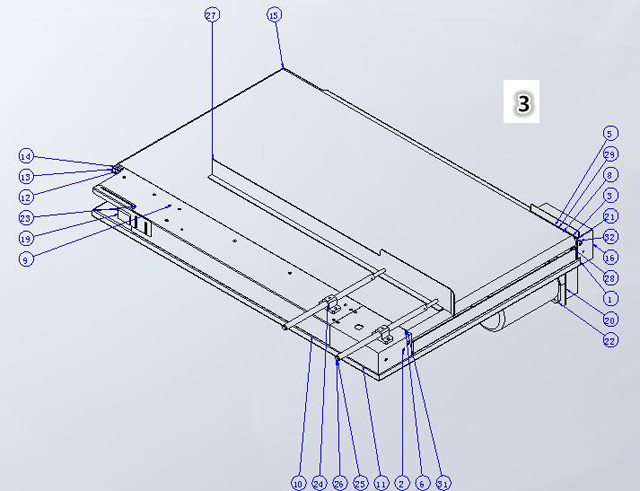

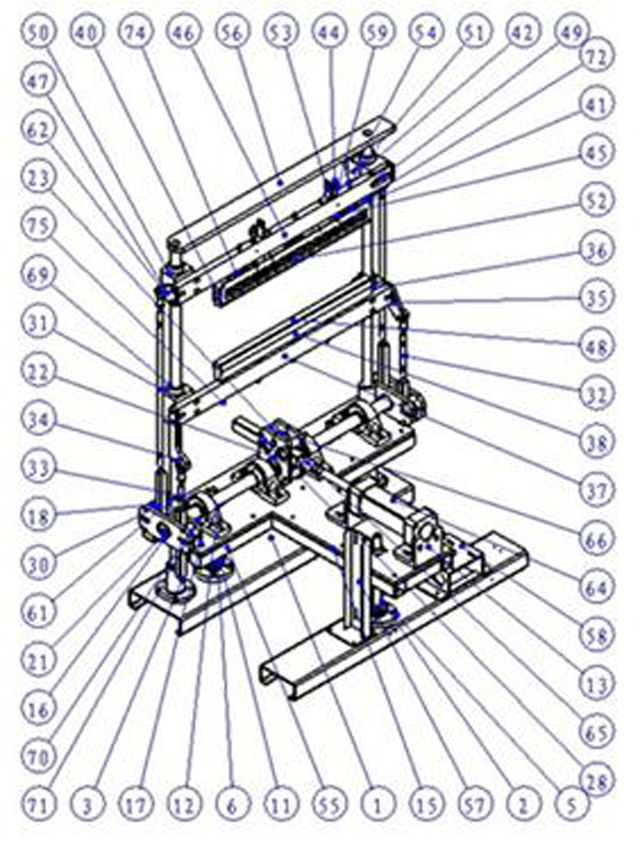

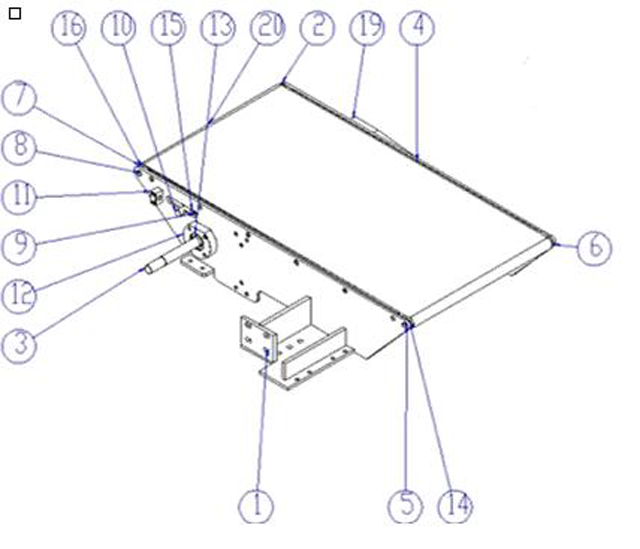

Illustrations of Machine Components

1、Machine assembly drawing

Alarm record Help

interface

No Name Quantity

2 Film feeding assembly 1

3 Front conveyor assembly 1

4 Horizontal seal assembly 1

5 Rear conveyor assembly 1

How to do Installation of Machine

A. Open the upper cover of the packing case and remove the four side plates of

the packing case;

B. Lift out the main body of the machine and place it on a stable ground;

C. Adjust the anchor bolts at the bottom of the machine to adjust the horizontal

height of the machine and prevent the machine from sliding during operation;

D. Please wire according to the voltage shown on the nameplate and connect the

air source. Note: be sure to connect the ground wire reliably.

Operation Method of Machine

1. Turn on the main power switch, and the machine will enter the power on

state;

2. Connect the air source and adjust the air pressure to 6.0 ~ 8.0Gg/cm2;

3. Press the control button of the horizontal seal and side seal temperature

controller to adjust the horizontal seal temperature to 200~220 ℃ and the

side seal temperature to 280~300 ℃;

4. Select appropriate packaging materials according to the required packaging

material specifications (calculation formula, height+width+"4~6");

5. Place the packaged products at the beveled edge of the triangular plate on the

feeding conveyor line, adjust the triangular plate to 5-8 mm higher than

the product, and then adjust the side limit strip to 5-8 mm away from the

product, so that the product can run smoothly on the feeding belt line

without jamming;

6. With the side stop strip as the benchmark, adjust the feeding belt line to the

front of the side seal shield, depending on the product margin;

7. Adjust the edge seal height to the height of the object to be packaged ½ ,

subject to the section of membrane puller;

8. Adjust the horizontal seal height to the height of the object to be packed ½

The height of the contact surface can be changed by touching the up and

down buttons on the touch screen based on the contact between the

sealing knife and the lower knife base;

9. Select the detection method (horizontal photoelectric, vertical photoelectric)

suitable for the product according to the height and shape of the product;

10. Draw the packaging materials to the side seal in order according to the

schematic direction, rotate the lifting handle of the side seal to make the

packaging materials flat in the film pulling belt, reset the lifting handle, touch the

discharge belt to run, and then pull the waste film to the reel according to the film

collecting schematic diagram after the waste film is removed;

11. After the operation interface is switched to the automatic menu, start the

automatic operation. After putting in the articles to be packaged for trial

production, check whether the front and rear margins are appropriate. Adjust them

by turning to the parameter setting menu, and batch production can be started

until they are appropriate;

12. After the work is completed, turn off the heating button, turn off the main

power supply and turn off the air supply.

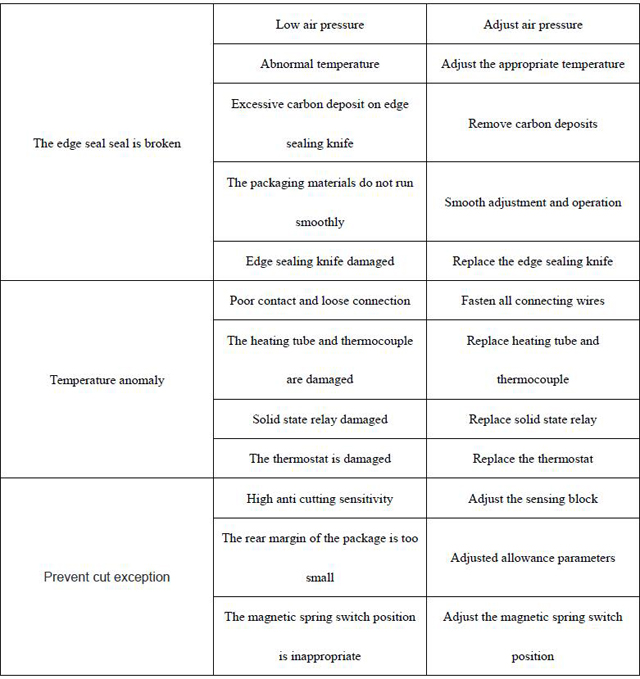

Maintenance of Machine

A. After the machine works, remove the residues and dust of the machine;

B. Regularly check all sliding and running parts and add lubricating oil;

C. Regularly remove the carbon deposit on the sealing knife. It is forbidden to use

metal parts to remove it

D. The overall performance shall be checked once a month.

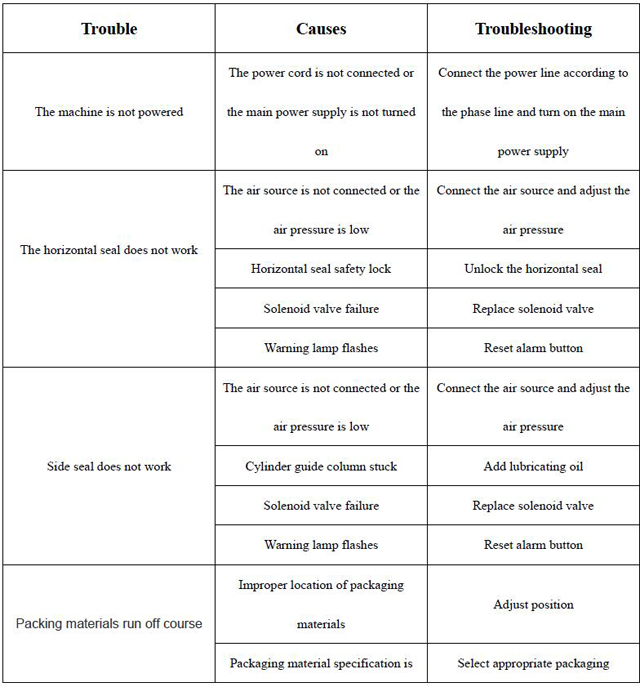

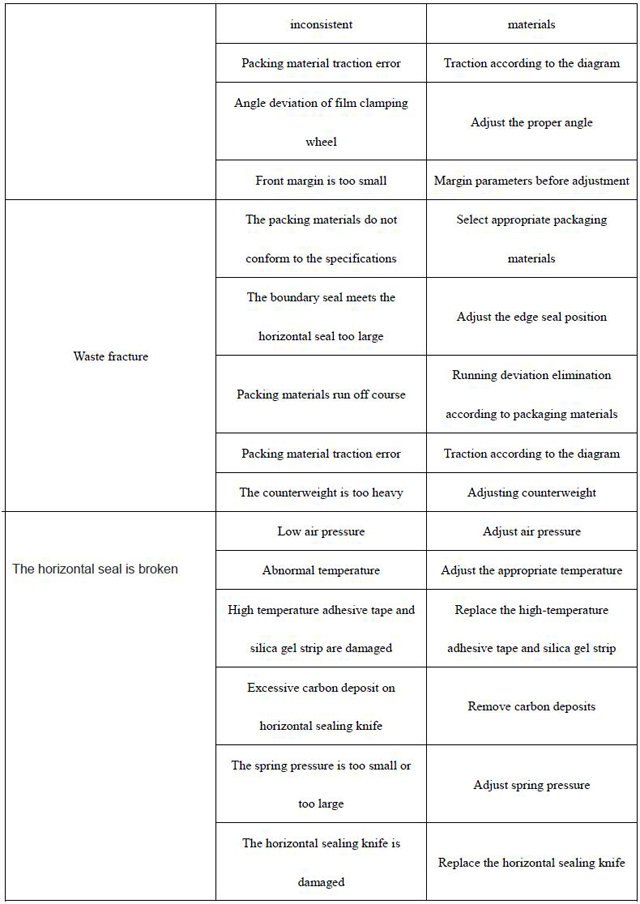

Troubleshooting

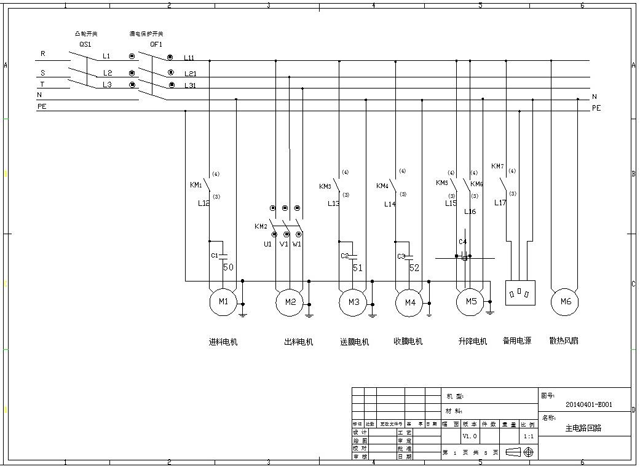

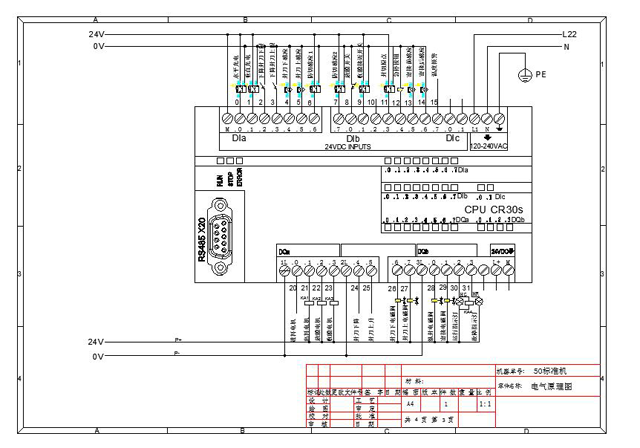

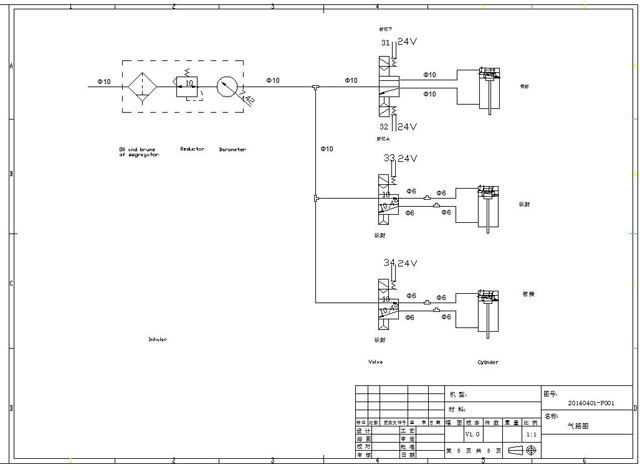

Circuit Diagram of the Machine

Packing List

No Name Spec Quantity

1 Machine host 1 set

2 The toolkit 1

3 Hex socket wrench 1 set

4 Adjustable wrench 1

5 The screwdriver 1

6 thermocouple 1

7 The silicone article 1

8 The high temperature tape 1 roll

@PENGLAI INDUSTRIAL CORPORATION LIMITEDDownload the Manual books of Sealing and shrinkage tunnel

Previous: round cans seaming canning machine automatic vacuum seamer equipment speed 40ppm for fast food tin c

Next: Return

Tel: +86-755—86718316 Fax: +86-755—25417648

Email: jackdu999@yahoo.com

Copyright @ 2003-2021 SHENZHEN PENGLAI Industrial Corporation Limited. All rights reserved