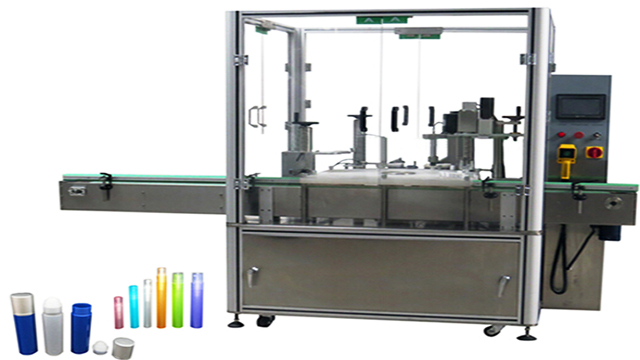

Nail polish eye drops filling capping machine with mechanic robot fully automatic rotary filler capp

Model YX-40G filling capping machine with mechanic robot fully automatic rotary filler capper servor motor system for Nail polish eye drops

Bottle Inlet Machine automatic bottles unscrambler

1. This machine applies to foodstuff, pharmacy, cosmetic, chemical and pesticide industries.

2. Suitable diameter of bottles: Ф40mm~Ф100mm 3. It utilizes stepless speed regulation technology.

Major Characteristics The template of this machine adopts stepless speed adjust foe slew, make all the bottles enter into conveyer belt in order under the rotary tangential force, less labor, boost production efficiency.

This machine can be used after electrified. Easing operating, it can be widely used for glass bottles, plastic bottles and polyester bottles for pharmaceutical, agrochemical, food, chemical etc.

it is a good choice for small, medium, large factory.

Main Performance Parameter: 1.Machine dimension (L×W×H) : 1700mm×1300mm×1350mm 2.Weight of machine : 300kg 3

.Suitable diameter of bottles : Ф40mm~Ф100mm 4.Diameter of turntable : Ф600-1000mm 5.Power supply : AC 220V; 50Hz 6.Power : 1.5kw 7.Production capacity : 60~120bottles/minute

Manipulator type double liquid filling machine is the latest product of my company developed in recent years, with the

microcomputer steps set wriggle pump machine adopts precision ceramic pump) (special occasions and has the automatic

filling, automatic plug, screw cover a variety of functions. Under the machine configuration domestic unique dedicated

manipulator, and screw cap in the form of swing arm, accurate under cover, screw cap adopt servo motor torque mode,

screw cap firmness, convenient adjustment so as to realize fully automated.

Features of rotary filling capping machine

1. The setting of the microcomputer, the load precision, convenient operation.

2. The filling system can be customized to suction function, no drop leak.

3. Using manipulator automatic brush, spiral cover.

4. Automatic stop function, for any orbital consecutive without filling, automatic stop without cover.

Technical parameters of model YX-40G rotary filling capping machine with manipulator(mechanical robot)

Model YX-40G

Applicable specifications: 2-30 ml

Production capacity: 40-60 / minute

Filling accuracy: + / - 0.5% or less;

Power supply: 22 v50hz

Spin (rolling) cover rate: 99% or higher

Automatic plug rate: 99% or higher

Source: 2 m3 / h, 0.4 to 0.8 Mpa

Power: 1.0 KW

Machine net weight: 400 kg

Dimension: 2400 * 1100 * 1500 mm

Basic configuration for model YX-40G filling capping machine with mechanical robot

|

Number |

Item |

Model |

Brand |

Number |

Mark |

|

1 |

Touch screen |

TK6070IK |

Wenview |

1 |

|

|

2 |

PLC controller |

DVP-32EH00T3 |

Delta |

1 |

|

|

3 |

plc module |

DVP08HN11T |

Delta |

1 |

|

|

4 |

Inverter |

VFD-M 1.5kw |

Delta |

1 |

Three phase 220V |

|

5 |

Inverter |

VFD-M 0.75KW |

Delta |

1 |

Three phase 220V |

|

6 |

Servor driver |

400W |

Delta |

1 |

Three phase 220V with motor |

|

7 |

photo-electric switch |

SICKWZ1251 |

|

5 |

|

|

8 |

Magnetic switch |

|

|

2 |

|

|

9 |

Rotary encoder |

|

OMRON |

1 |

|

|

10 |

Selenoid Valve |

|

|

11 |

24V coil |

|

11 |

Air Switch3P |

DZ47-60 D32 |

Chint |

1 |

|

|

12 |

Air Switch 2P |

DZ47-60 C25 |

CHINT |

1 |

|

|

23 |

AC Contactor |

LC1E2510 |

Schneider |

1 |

|

|

24 |

Imediate Relay |

RXM2LB2BD 24V5A |

Schneider |

4 |

|

|

25 |

Switch |

NES-100-24 |

Mingwei |

1 |

|

|

26 |

Overload Microswitch |

TZ7311 |

TEND |

1 |

with Glove |

|

27 |

Door-trip |

|

|

8 |

with Glove |

|

28 |

Terminal |

|

|

1 |

50Bitmap Common |

|

29 |

Terminal |

|

|

1 |

10Bitmap Common |

|

30 |

Micarta |

|

|

1 |

|

Accessory part for rotary filling sealing machine:

40L material tank with SUS316 stainless steel contact part

Vibrator bowls for caps automatic falling system

EX wire boxes for combustible&volatile liquid

Samples from model YX-40G as final product like perfume liquid

After-sales service of filling capping machine for cosmetic&pharma liquid

Guarantee: for all the machine, it claims one year for guarantee.(Excluded from the warranty are problems due to accidents, misuse , misapplication, storage damage, negligence, or modification to the Equipment or its components.

ALSO THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

Installation: after the machine arrive your factory,if you need,our technician will go to your place to install and test the machine and also training your worker to operating the machine (The time of train depend on you worker).

The expenses (air ticket ,food , hotel,the travelling fee on your country) should be on your account and you need paid for the technician USD50 per day. also you can go to our factory to do training.

After service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible. The cost should be in your account.(as above).

®PENGLAI INDUSTRIAL CORPORATION LIMITED

Previous: honey cream thick sauce forming filling sealing machine cups filler sealer equipment fully automatic

Next: plastic bottles milk gravity filling foil film forming sealing line automatic liquid filler sealer c

Tel: +86-755—86718316 Fax: +86-755—25417648

Email: jackdu999@yahoo.com

Copyright @ 2003-2021 SHENZHEN PENGLAI Industrial Corporation Limited. All rights reserved