inline trays sealing machine automatic heat sealer equipment for fast food trays cups buckets

Automatic tray sealing machine can detect filled trays, auto gas flushing into tray (optional), auto sealing trays by plastic film, film pulling and positioning, auto printing the produce date(optional), auto collect the waste film, auto discharging the finish products. Base on different mold quantity, its capacity from 800-2400cups per hour, suitable for factory production needs.

Category of the sealing machines in the page:

1. features of trays sealing machine;

2.drawing &configuration of trays sealer;

3.specifications of trays sealing machine;

4.guide how to use and learn the trays sealing machine;

5.details of trays sealing machine;

6.samples of trays for sealing;

7.wooden case before shipping the trays sealing machine;

Whole machine made by stainless steel 304 and anodizing aluminum, ensure it can running on bad food factory environment which has damp, steam, oil, acidity and salt etc. its body can accept the water rinsing clean.

Using high quality imported electrical parts and pneumatic parts which ensure the stable running in long time, reduce the stop and maintenance time.

Chain driven system: servo motor with gearbox for the chain stepping running, it can move very fast but avoid material splash because servo motor can start and stop smoothly, and also high positioning accuracy.

Filled tray detecting function: it uses photoelectric sensor or optical fiber sensor to detect the conveyor have or haven’t tray, it can avoid the mistake sealing if the conveyor without the tray, reduce the product waste and save machine cleaning time.

Gas flushing function(optional): the film will be press tight on top of the tray, then flushing the gas on the top of the tray, drive out the oxygen and air out of tray then seal the tray.

Sealing cutting coding system: it makes up by heating sealing mold, film cutter, film pressing tensioner, spot mark positioning system and waste film collecting function. It can seal the tray, cutting the film and printing the produce date fast and accuracy.

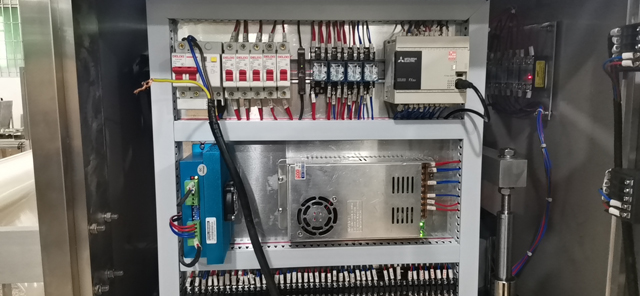

Automation control system: it make up by PLC, Touch screen, servo system, sensor, magnetic valve, relays etc.

Pneumatic system: it make up by valve, air filter, meter, pressing sensor, magnetic valve, air cylinders, silencer etc.

Safety guards: it is optional function, it makes up by PC plates and stainless steel, has safety switches which protect the operator.

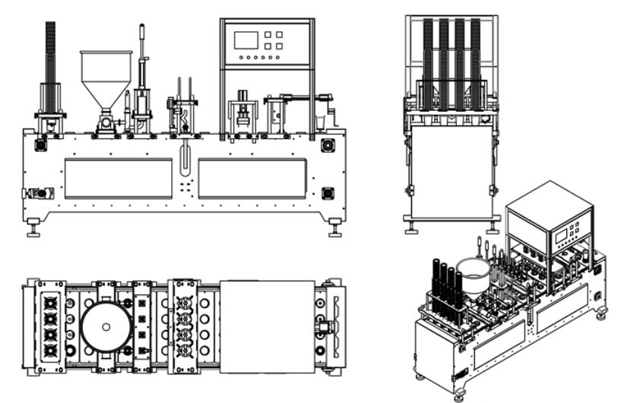

►Configuration of trays sealing machine:

inside tray sealing machinery.jpg

♦Pneumatic system: AIRTAC

♦Servo system: HAIDE

♦Reduce gearbox: JIE

♦Film pulling motor: DONGLI

♦PLC: Mitsubishi

♦Touch screen: WEINVIEW

♦PID temperature controller: Omron

♦Sensor: Omron, FOTEK

♦low-voltage: Omron, Schneider, CHNT

Model YX-440A single tray sealing machine YX-440AA double trays sealing machine

Capacity 800-1000cups per hour 1600-2000cups per hour

Voltage 1P 220v50hz or customize 1P 220v50hz or customize

Total power 1.8KW 2.4kw

Filling Volume 240*180*80mm 240*180*80mm

Air Pressure 0.6-0.8Mpa 0.6-0.8Mpa

Air Consumption ≤0.3m3/min ≤0.3m3/min

Machine size 2200*800*1900mm 2200*1100*1900mm

Machine Weight 650kg 780kg

Marks:

Optional function of inline sealing trays machine:

♦Gas flushing function

♦Date coder

♦Sus304 safety cover & door switch

♦Auto filled tray feeder

How to use the automatic cup sealing machine?

When in use, the first thing to do is to turn on the power switch. We waited until the indicator light inside the button lights up. Then adjust the speed of the automatic cup sealing machine. Speed adjustment refers to adjusting the speed of the inner conveyor belt of the cup sealing machine. This can better cooperate with production. The next step is to adjust the temperature. We need to change the temperature to a better state. When the temperature reaches a specific value, the temperature indicator of the automatic cup sealing machine will give a hint. Then can carry out the sealing operation.

Through the brief introduction of this article. Do you think that the use of the automatic cup sealing machine is straightforward? That’s right. The above are the simple steps to use the automatic cup sealing machine. Because the device’s design is very advanced and reasonable, every step of the automatic cup sealing machine will have specific prompts. We only need to follow the prompts when using it. In this way, the operation of the automatic cup sealing machine will become simpler and faster.

In addition, reasonable use of the automatic cup sealing machine can effectively guarantee the service life of the device itself. Therefore, no matter what kind of mechanical equipment, we must have the correct use method so that it will be safer to use, and at the same time, it can guarantee the service life of the equipment.

Working principles of cups sealing machine:

When the package containing the items is placed on the conveyor belt, the sealing part of the tray is automatically fed between the two sealing belts in operation and brought into the heating zone. The heat of the heating block is transferred to the sealing part of the bag through the sealing belt. The film is heated and melted, and then passed through the cooling zone to make the surface temperature of the film drop appropriately, and then rolled by the knurling wheel (or printing wheel), so that the upper and lower plastic films of the sealing part are bonded and pressed into a net pattern (or printed logo) ), and then the sealed packaging bag is sent out of the machine by the guiding rubber belt and conveyor belt to complete the sealing operation.

1. This meal tray sealer is mainly used for heating and sealing polyolefin (such as polyethylene, polypropylene, etc.) as the inner layer of composite film materials and plastic bag sealing.

2. Composite film sealing includes cellophane sealing, aluminum foil sealing, aluminum spray coating sealing, polyester sealing, nylon sealing, polyethylene sealing, polypropylene sealing and other materials sealing.

3. The thickness of the film and the width of the sealing can be applied within a certain range, and a good and uniform linear sealing can be achieved.

4. The machine is exquisitely designed and easy to operate.

ALL RIGHTS RESERVED by ®PENGLAI INDUSTRIAL CORPORATION LIMITED

Previous: Automatic Disposable Cup Face Mask Forming Making Machine N95 masks with breathing valve production

Next: round cans seaming canning machine automatic vacuum seamer equipment speed 40ppm for fast food tin c

Tel: +86-755—86718316 Fax: +86-755—25417648

Email: jackdu999@yahoo.com

Copyright @ 2003-2021 SHENZHEN PENGLAI Industrial Corporation Limited. All rights reserved