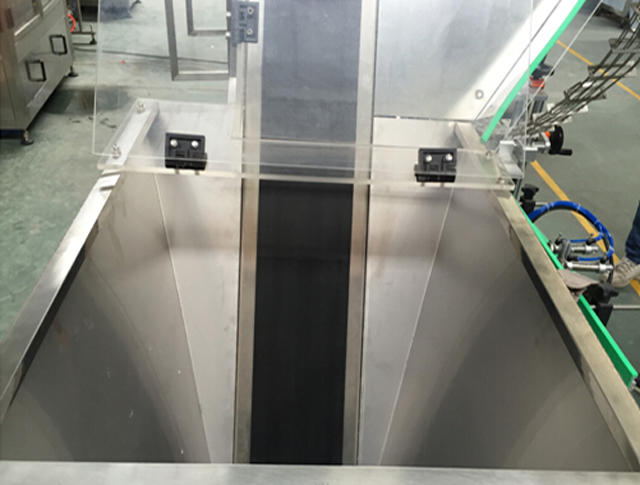

Jars Caps belt lifting feeding system automatic Accessory equipment for high-speed capping machine

Caps Lifting Loading Feeding Equipment Accessory Equipment for Filling Line

caps loading system integrated with coconut oil filling line

I. Adopting microswitch detection technology, the machine conveys the caps from the hopper to the cap sorter with constant speed, ensuring the caps in the cap sorter in the best condition. The caps loading speed can be adjusted anytime and cap loading automatically stops when the cap sorter is full. This machine is in conformity with GMP requirements.

Performance advantages:

1.Control system----.Operation system ---- Adopting traditional control plate, easy-operated , stable and reliable

2.Function advantage----Supporting with the capping machine,automatic cap-sender,automatic stopping,automatic control.

3.Stepless speed regulation---- According to production requirement can realize balance the cap-sending speed .

4.Electrical elements----Adopting international famous brand to ensure the remarkable quality, stability and high precision.

5.Machine elements----The parts contacted with the material use the 304 high-quality stainless steel 6.Maintenance condition----Fully accords to the GMP requirements, easy to disassemble and clean.

II. Main Parameters:

1. Caps loading speed: ≤12000 pcs/hour

2. Power supply:220V

3. Total Power:0.12kw

4. Dimensions: 800mm × 600mm × 2000mm

5. Net Weight:100kg

6.Belt width :200mm

7.Belt Length:2600mm

Caps loadiing in pictures for all details integrated with capping machine high speed

BL cap bottle screw nut can pin bag berry belt bulk conveyor lifter

Bottles caps lifting feeding system integrated with vacuum capping machine

Bottles jars samples for caps lifting feeding

Optional caps feeding system for capping machine

Vibratory bowl for small caps pictures

Videos of how the vibrator works for caps feeding system

After sales service:

After sales service shall be done by the seller.

PENGLAI machine will provide all kinds of technical support

to the buyer by telephone, fax or e-mail free of charge.

But any service cost to buyer's country is not included.

Guarantee: one year. The supplier can replace only the elements

that are imperfect for material or handwork.

Replacement is free and ex factory.All imperfect elements

have to be delivered within 12 months (carriage paid).

Guarantee excludes every worn or torn parts.

Replacement handwork is excluded and it will be done by the buyer.

The supplier is not responsible for any rewards for, damages or last earnings met by buyer.

Guarantee is not valid if the machine is used the wrong way

or it is not serviced as shown in our technical handbook.

Previous: caps inserting machine automatic cap wadding equipment vibrator caps lining machinery

Next: Automatic Two-Cap Combining Assembly Machine high speed rotary push-pull ring seal caps lining equip

Tel: +86-755—86718316 Fax: +86-755—25417648

Email: jackdu999@yahoo.com

Copyright @ 2003-2021 SHENZHEN PENGLAI Industrial Corporation Limited. All rights reserved