ultrasound sealing equipment small ultrasonic sealer machinery semi automatic for soft tubes laminat

Model YX-005 Ultrasonic Tube Sealer can weld the tail of soft tube. It's wildly used in cosmetic, toothpaste, commodity, medicine, chemical, and other types of tube tail sealing.

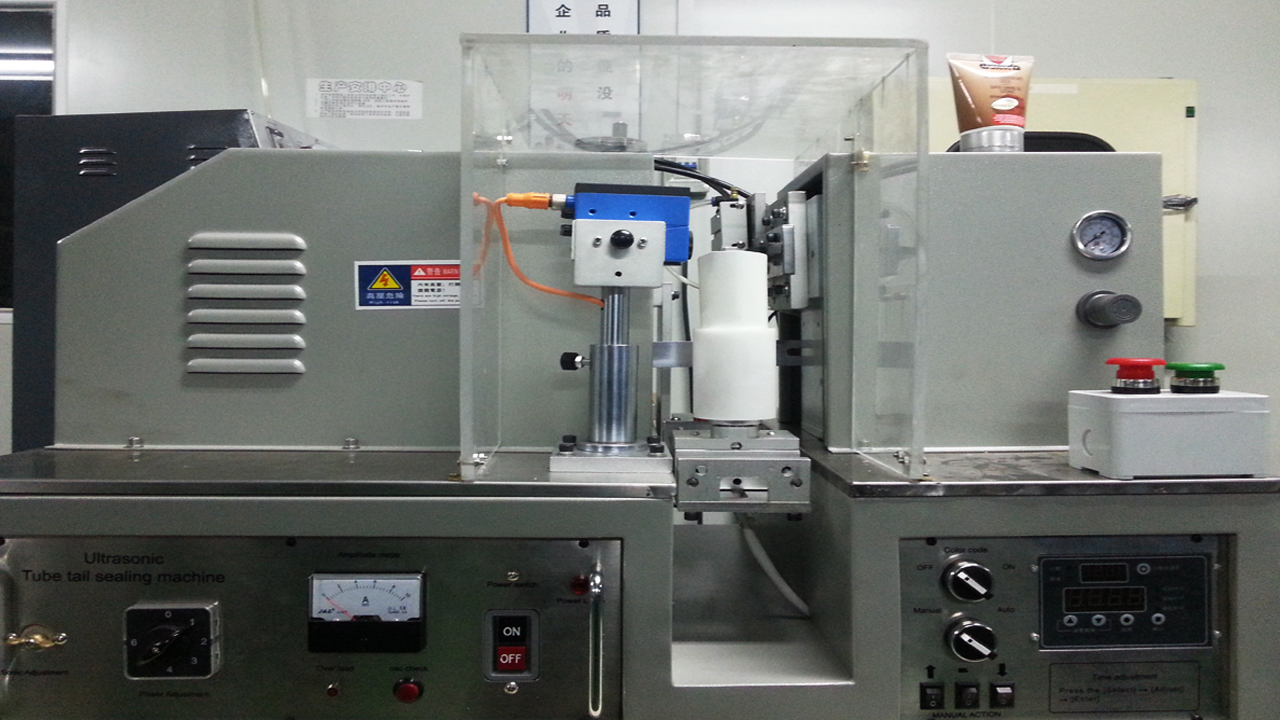

2. Ultrasonic Tube Sealer view:

3.Special Function of Ultrasonic Tube Sealer(The machine can be integrated with filling machine to function filling sealing tubes)

4.Main features

1. Easy to operate and maintain.

2.Automatic positioning, welding, cutting and trimming, printing code in one time.

3.. Stainless steel machine body, strong and beautiful,

4,The machine small enough to be put on worktable.

5. Sealing mould can be customized according to customer requirements. Can seal many size of tubes.

6. Ultrasonic Sealing Machine power source for the pneumatic, working steady, not easy to damage, customers can rest assured use.

7. Ultrasonic frequency can meet international standard, no harmful to human being or environment

8. Ultrasonic Tube Sealer can be work in time, not need wait the heat time .

5. Ultrasonic Tube Sealer Package :

6.Spare parts list from Model YX-005 Ultrasonic tubes sealing machine :

7.Basic parameter of model YX-005 Plastic tubes sealer equipment semi automatic:

Application: toothpaste, cosmetics, medicines, food, industrial supplies,

|

Items |

Parameter |

|

Model |

YX-005 |

|

Frequency: |

20Khz |

|

Ultrasonic power: |

1500W |

|

Power Voltage |

AC220V/50Hz |

|

Output power |

1200W |

|

Length of tube |

50-250mm |

|

sealing Dia |

10-80 mm |

|

Time adjust: |

Electronic adjust |

|

N.W/G.W |

110KGS/150KGS |

|

H.S code: |

8515800090 |

|

Pack size |

1050×760×790mm(0.33 CBM) |

|

Pack |

Plywood wooden case |

8.FAQ about Model YX-005 Ultrasound plastic tubes sealing equipment:

1.If i order this machine , how to operation it ?

Answer: Ultrasonic Tube Sealer is easy and simple operation, you just connect the electricity , and air compress machine

2.About Guarantee:

Answer: one year. The supplier can replace only the elements that are imperfect for material or handwork. Replacement is free. All imperfect elements have to be delivered within 12 months (carriage paid). Guarantee excludes every worn or torn parts. Replacement handwork is excluded and it will be done by the buyer. The supplier is not responsible for any rewards for, damages or last earnings met by buyer. Guarantee is not valid if the machine is used the wrong way or it is not serviced as shown in our technical handbook.

3.Do you have other model ?

Answer: Of course . we have semi-automatic type (YX-005) and Automatic filling and sealing machine for you .Please view our Home page .

4.What is the power supply?

Answer : we can design according to your inquiry . usually it is :220V/ 1 phase . 110V/single phase.

5.Is this machine need mould ?

Answer: yes it need mould . The machine will one pc welding mould free in charge.

After sales service: After sales service shall be done by the buyer.

PENGLAI machine will provide all kinds of technical support to the buyer by telephone, fax or e-mail free of charge.But any service cost to buyer's country is not included.

Guarantee: one year. The supplier can replace only the elements that are imperfect for material or handwork.Replacement is free and ex factory.

All imperfect elements have to be delivered within 12 months (carriage paid).

Guarantee excludes every worn or torn parts. Replacement handwork is excluded and it will be done by the buyer.

The supplier is not responsible for any rewards for, damages or last earnings met by buyer.

Guarantee is not valid if the machine is used the wrong way or it is not serviced as shown in our technical handbook.

Annotation: How does ultrasonic welding(sealing) work?

Ultrasonic welding is a process used to join two plastic parts together to form a strong, finished assembly. The process relies on high-frequency (ultrasonic) vibrations being generated and applied to the parts via a horn. Welding occurs as the vibrations are absorbed in the interface between the two parts, generating friction and causing the plastic to melt. The ultrasonic vibrations are generated by a series of components, including the power supply, converter, booster and horn, which ultimately delivers the mechanical vibration to the parts.

The role of the power supply is to convert the incoming line voltage (at 50 or 60Hz) into a new frequency. This electrical energy then is sent to the converter, which as the name implies, converts the electrical energy into mechanical vibrations. The converter consists of piezoelectric ceramic discs, which expand and contract at the rate of the supplied electrical energy. The magnitude of the vibrations is referred to as amplitude, a term that becomes very important when specifying an ultrasonic system for a given application. The vibrations then are transmitted through the booster, which typically increases the amplitude by a predetermined multiple, also known as gain. Finally, the booster’s output amplitude is transmitted through the horn, where it then can be delivered to the plastic parts. The combination of converter, booster and horn is commonly referred to as the ultrasonic stack.

To deliver the vibrations to the parts, the stack is placed in an actuator, a mechanical system that applies the next critical element of ultrasonic welding: force. The actuator may consist of a pneumatic cylinder or other means of actuation to drive the stack down to the part. Actuators often contain other sensors and devices, such as linear encoders or load cells, to provide feedback during the weld. The actuator drives the horn down to the part and applies force until a trigger force is met; at this point, ultrasonics is applied. The vibrations then are delivered to the parts, where they become focused on a triangular bead of material – known as an “energy director” – which can be considered sacrificial melt material in the weld joint. Once the material melts, the ultrasonic vibrations are terminated and the actuator continues pressure until the plastic is solidified and a strong bond is formed. The entire weld process, from start to finish, typically is completed in one to two seconds.

As mentioned, one of the most important elements of ultrasonic welding is the amplitude (vibrations) that the stack provides. The reason for this is that certain plastics require more amplitude to weld than others. Amorphous polymers (ABS, polycarbonate, polystyrene) tend to require low amplitude, while semi-crystallines (nylon, polypropylene) require significantly more amplitude to weld.

An experienced applications engineer always can work to determine the proper frequency and tooling selection for a given assembly and material type.

Ultrasonic welding is a widely accepted assembly method in the plastics industry for a variety of component assembly applications in all major markets: medical, B&CE, automotive, appliance, nonwovens, packaging and more. Advantages to ultrasonic welding include short cycle time, high-strength bonds and the elimination of consumables (i.e., adhesives). When considering whether ultrasonic welding is right for an application, it is best to consult an experienced applications engineer to determine the appropriate assembly method.

PENGLAI INDUSTRIAL CORPORATION LIMITEd

Previous: Return

Next: Ultrasonic tubes plastic laminated soft tube sealing machinery semi automatic ultrasound sealer equi

Tel: +86-755—86718316 Fax: +86-755—25417648

Email: jackdu999@yahoo.com

Copyright @ 2003-2021 SHENZHEN PENGLAI Industrial Corporation Limited. All rights reserved