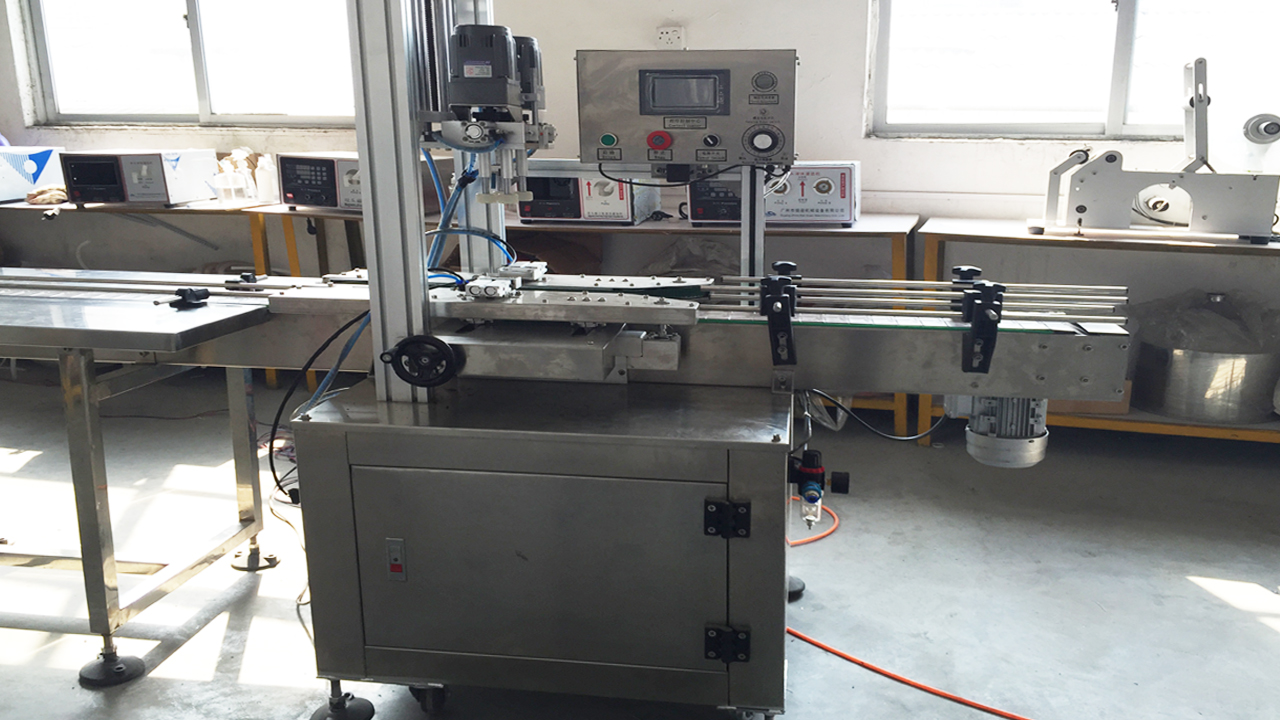

Linear capping machine with bottles sensor clamping system automatic bottle jar container capper equ

Model YX-SCM003 Linear capping machine automatic with bottles sensor&clamping system during capping

Application OF Screw capping machine automatic linear model YX-SCM003

This linear capping machine is mainly used in cosmetics, pharmaceuticals, veterinary drugs, pesticides, oil etc. industries, cap tightening and loosening equipment.

Basic parameter of linear capping machine with automatic sensor clamping system bottles model

YX-SCM003

Supply power AC220V 50HZ

Power 650W

Size 2000L*650W*1500H[MM]

Net weight 180KG

Air pressure 0.4—0.6MPa

Caps diameter 18mm≤Φ≤150 mm

Bottles height 50-400mm Width 20-200mm

Speed 30—40PCS/Min

Torsion 4--8kg/cm

Basic features for screw capping machine linear model YX-SCM003

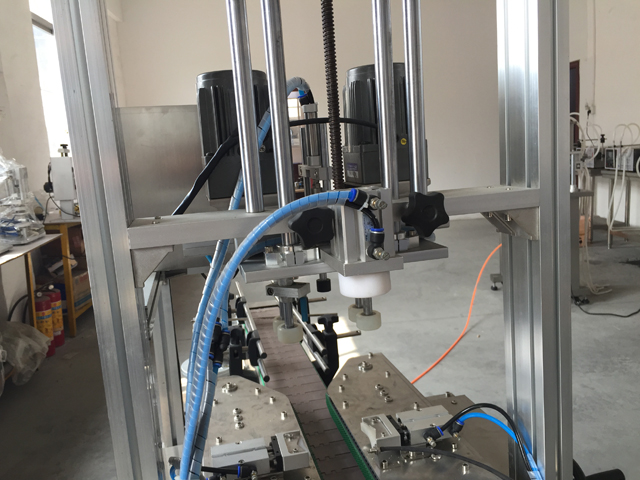

Touch screen controlling system for capping machines

capping head and touch screen shot

1)This screw capping machinery Suitable for automatic capping in cosmetic,medicine and drink,etc

2)Good looking,easy to operate;

3)Competitive price offer;

4)Manual feeding bottles on the conveyor belt;

5) there are the pressing position system during screw capping;

Final products after being screw-capped for the jars&bottles

Packaging of screw capping machine in wooden case

Our machines has already exported to the most countries in the world .That is not only because the great

quality of our machinery but also because that we can customize various machines according to the special

requirements from our customers and the samples sent from the buyers .

We often test the machine many times with the samples sent from the buyer then seek the best solution and

effect .

below is the case that we have done the rotary capping machine automatic in high speed with caps

feeeding vibrators according to our US customer unique requests in speed for his shampoo production line.

As follow is the basic information like detailed pictures one by one .for more details please feel free to

contact us via email or skype us online

Model YX-SCM004 rotary screw capping machines with multiplates for feeding

Shampoo bottles in conveyor belt for feeding under the screw capping head

Feeding plates for caps falling from the vibrator in Model YX-SCM004 rotary capper high speed

Inside electroc boxes for model YX-SCM004 rotary screw capping machinery

Rotary mould plate for main body of screw capping machine rotary model YX-SCM004

FAQ-Frequently Asked Questions

1. Q: How can I be sure to get assurance &what I purchased after payment?

A: In China, there is anti-money laundry policy, for which the government strictly manages every payment from abroad. The payment you made will firstly go to their managing account, and only when we submit bill of loading to them, payment will be released to us;

the payment will be returned to you or pended by State Administration of Foreign Exchange,SAFE. if we are not able to make shipment and submit bill of lading within lead time.

We,in addition,have exported different kinds of packaging machinery to more than 150 countries and are able to offer you the reference list among cooperating customers to verificate our business and company.

2. Q: How can I be sure the machine will absolutely work for my product?

A: We will test run the machine once the building completes for 10 minutes, with your sample product ( when sample product is a must) and send you test run video to prove the machine works well and stable, for your product, before balance payment and shipment.

3. Q: Will you send technical staff to help me with installation and operation training?

A: The machine will be packed with little disassembly in one plywood crate, so they will be plug and use type, no need special installation.

And we will also send you installation and operating tutorial videos before shipment.Remote assistance by video call or meeting is available as well.

In rare cases, we can send technical staff if desperately needed, but there is 150USD/day engineer salary and flight ticket, visa application, travelling, board and lodging shall be at buyer's account.

4. Q: How many years warranty and how do I do the machine repairing and maintenance?

A: One-year warranty from the date of shipment, during which if any parts fault, we will courier to your replacing parts with replacing instructions, all at our cost.

The replacing is simple and easy to be completed by anybody.

The machines are maintenance free types, some daily lubrication will prolong the service life though.

5. Q: When can i expect my email or questions to be replied?

A: Our working time is 9:00am--18:00pm Monday--Saturday, any email shall be replied within 24 hours normally.WhatsApp better if in urgence.

For an enquiry, the most recommended way of contact is by email, by sending your final product&photos to our emails above-mentioned, due to our possible time difference.

6.Q: How long can I receive machine if I place the order?

A:Machine building takes 3-60 work days depending on the degree if customization.

Tabletop small machines usually takes only 3-7 work days to build, and larger, more customized machines normally takes 20 work days.

Some very customized built machines that require designing from scratch ,may take 40 work days or even more.

Shipping time will be 3-40 days depending on the shipping service you choose( courier, air or ocean shipping) and the distance of the ship-to country from China.

7.Q: How to preceed the business to buy PENGLAI-Branded Machines?

A:Customer confirms to order--Supplier sends Proforma Invoice--Customer pays 50% prepayment by wire transfer&sends out samples to be test run on machine to be built--Supplier starts the designing of machine after confirming receival of payment and sample--starts raw material purchasing--

processing of parts--assembling parts--PLC programming&commisioning--machine test run with the samples and sends test run video to customer for approval--test run video approved--customer pays balance--supplier makes plywood crates and processes shipping--supplier sends the needed import customs clearance documents

--machine received and cusomer easily installs and operates the machine,with the tutorial video by supplier--Any issues with operation, customer sends video demo and supplier responds with tutorial video.

After-sales terms for automatic screw capping machine with caps manual feeding:

Guarantee: for all the machine, it claims three years for guarantee.(Excluded from the warranty are problems due to accidents, misuse ,

misapplication, storage damage, negligence, or modification to the Equipment or its components. ALSO THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

Installation: after the machine arrive your factory,if you need,our technician will go to your place to install and test the machine and also training your worker to operating the machine

(The time of train depend on you worker). The expenses (air ticket ,food , hotel,the travelling fee on your country) should be on your account

and you need paid for the technician USD50 per day. also you can go to our factory to do training.

After service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible. The cost should be in your account.(as above).

Previous: inline screw capping machine for cream jars shampoo bottles manual feeding caps screw capper equipme

Next: automatic inline metal caps aluminum ropp capping machinery glass bottles capper equipment screw chu

Tel: +86-755—86718316 Fax: +86-755—25417648

Email: jackdu999@yahoo.com

Copyright @ 2003-2021 SHENZHEN PENGLAI Industrial Corporation Limited. All rights reserved