UAE customer orders another set of plane labeling machine semi automatic for plane surface perfume b

Our old customer Ms Julie from Karama Bur post code 214855 Dubai UAE placed another order for model YX-LM510 plane surface labeling machine for

her perfume bottles labelling .We done and test the machine in the same way as the last time and sent the goods to the assigned warehouse

in Guangzhou .Thanks for the trust and interest from our old friend!

Below is the basic information for this internation transaction :

Samples sent from customer like rolls of labels&perfume botltes

Customer pay the goods via ICBC to our company account

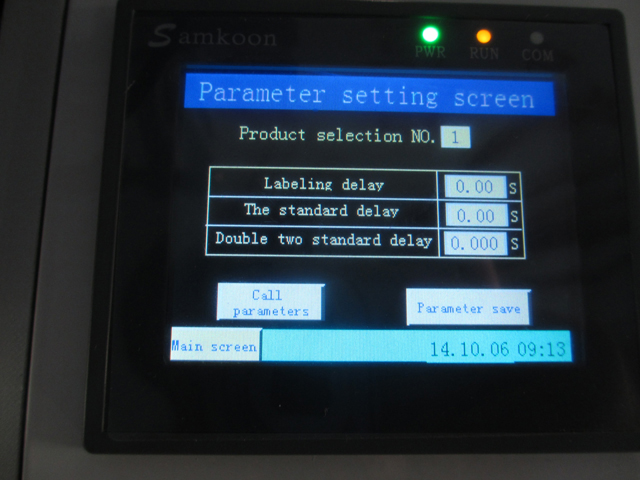

Testing run of model YX-LM510 for our mid-east customer

final packing before delivery of labeling machine to the warehouse

as follow is the basic information for the labeling machines

Flat labeling machines semi automatic with PLC screen manual plastic bottles labeler equipment máquina de etiquetadodesigned and manufactured by our engineer team in cosmetic&food&pharma making and packaging machinery is widely used in the daily chemical industry like Flat labeling machines semi automatic with PLC screen manual plastic bottles labeler equipment máquina de etiquetado and such like.We as a famous manufacturer moreover can design and produce the packaging machine according to the special requirements from customers.

In order to meet the needs of small business, factory to save labor, but also improve the quality of product label, especially the development of mini type semi automatic labeling machine, labeling process to achieve automatic operation, simple operation, fast production speed, uniform labeling position, beautiful, neat; applicable to pharmaceutical, chemical, food and other industries planar container, or a cambered surface vessels.

Working principle

The different packing object in labeling machine platform, press start switch, comprises a radiation calibration device label spit into the vacuum chuck, the pressing mechanism of the label to a bottle.

Product features

1,Process: manual Bottle Labeling - products.

2,This machine specially profiled in the product labeling, and for a variety of specifications of bottles and lids, wide applicable range.

3,For customers to custom-made mold, more convenient to use.

4,Pedal type touch emergency stop switch to ensure production safety, smooth operation.

5,Simple operation, anyone can easily operate fast using this device.

6,A label synchronous positioning mechanism, to ensure the positioning accuracy of 0.5mm in positive label.

Main technical parameters of Flat labeling machines semi automatic with PLC screen manual plastic bottles labeler equipment máquina de etiquetado:

Model YX-LM510

Working speed 1-50m/min

Labeling accuracy ±1mm

Labeling max width 120mm(Be designed and produced according to customer requirements)

N.W. 65KG

Label inner diameter Φ76.2mm

Label outer diameter Φ350mm

Machine size 1000×400×650mm

Using power 220V 50Hz 300W

Spare parts for labeling machine model YX-LM510 semi automatic plane surface bottles labeller:

Final labeling samples for customer:

Packaging pictures about our machine exported

crate size 850 * 505* 850mm weight : 70kg

Guarantee: for all the machine, it claims one year for guarantee.(Excluded from the warranty are problems due to accidents, misuse , misapplication, storage damage, negligence,

or modification to the Equipment or its components.

ALSO THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

Installation: after the machine arrive your factory,if you need,our technician will go to your place to install and test the machine

and also training your worker to operating the machine

(The time of train depend on you worker). The expenses (air ticket ,food , hotel,the travelling fee on your country)

should be on your account and you need paid for the technician

USD50 per day. also you can go to our factory to do training.

After service: If you get the problem on the machine ,our technician will go to your place

to fixed the machine as soon as possible.The cost should be in your account.(as above).

PENGLAI INDUSTRIAL CORPORATION LIMITED

Previous: US CA customer purchased two sets filling ultrasonic sealing induction sealer automatic for cosmetic

Next: USA Austin customer ordered&tested spout bags filling screw capping machine fully automatic with bag

Tel: +86-755—86718316 Fax: +86-755—25417648

Email: jackdu999@yahoo.com

Copyright @ 2003-2021 SHENZHEN PENGLAI Industrial Corporation Limited. All rights reserved